NEWS CENTER

Environmental corrosion of steel materials

- Categories:Company news

- Author:

- Origin:

- Time of issue:2020-05-07

- Views:3

(Summary description)This paper introduces the current status of the development of environmental corrosion test technology for steel materials at home and abroad, summarizes various test methods required in the research and development of new corrosion-resistant steel materials, and analyzes outdoor exposure tests, indoor simulated accelerated tests, online corrosion monitoring and large-scale testing.

Environmental corrosion of steel materials

(Summary description)This paper introduces the current status of the development of environmental corrosion test technology for steel materials at home and abroad, summarizes various test methods required in the research and development of new corrosion-resistant steel materials, and analyzes outdoor exposure tests, indoor simulated accelerated tests, online corrosion monitoring and large-scale testing.

- Categories:Company news

- Author:

- Origin:

- Time of issue:2020-05-07

- Views:3

|

Abstract: This paper introduces the current status of the development of environmental corrosion test technology for steel materials at home and abroad, summarizes various test methods required in the research and development of new corrosion-resistant steel materials, and analyzes outdoor exposure tests, indoor simulated accelerated tests, online corrosion monitoring and large-scale testing. Research focus and development trend of data evaluation technology. In view of the fact that the natural environmental corrosion test of steel materials is very important to ensure the safety and reliability of its service process, the establishment of a standardized and standardized environmental corrosion test technology system is an important work to improve the quality of my country's steel materials.

As the most important structural material, steel materials are used in almost all industries. With the development of energy industry, marine resources and shipbuilding industry, the demand for high-performance structural corrosion-resistant steel is becoming more and more urgent. However, steel materials will corrode under the influence of the environment. According to the data of the major consulting project of "my country's Corrosion Status and Control Strategy Research", the total corrosion cost of the entire industry in my country in 2014 accounted for about 3.34% of the gross domestic product (GDP), reaching 2.13 trillion RMB, corrosion products and failed materials/products also cause serious pollution and far-reaching impact on the environment. Since the corrosion data of steel in natural environments such as the atmosphere, soil and water has the characteristics of non-introduction, public welfare, long-term and continuity, the accumulation and sharing of scientific data on environmental corrosion of materials and standardized and standardized environmental corrosion test technology It is an extremely important basic work to improve the quality of steel materials in my country.

For a long time, the focus of research on environmental corrosion of steel materials has been around test equipment, technology, methods and standards. With the advent of the information age, data science has also played an important role in corrosion test research, whether it is corrosion tests in various natural environments under atmospheric, water, soil and microbial conditions, or stress corrosion, pitting and galvanic corrosion, etc. Types of local corrosion tests, including the overall corrosion resistance of components or equipment, have accumulated some data at home and abroad. With the use of high-throughput testing techniques and methods, the amount of data will increase rapidly. At the same time, data mining, support vector machines, Bayesian models and other data analysis and modeling methods also provide strong support for corrosion science research. These data and data analysis methods play an extremely important role in the in-depth study of corrosion mechanisms, long-term tracking of corrosion laws, the development of new corrosion-resistant alloys, the determination of corrosion control technologies, and the selection of materials for engineering design. The demand for data and information research in corrosion science is the driving force behind the generation and development of corrosion informatics.

Based on this, the article summarizes the environmental corrosion test technology of steel materials and the status quo of foreign research, provides basic information for its further application in China, provides references for the design, R&D, and manufacturing of steel materials, and provides materials for equipment selection in various environments. The theoretical basis is to improve the reliability and durability of my country's steel material products and equipment.

1 Natural environment exposure corrosion test technology

From the middle of the eighteenth century to the twenty-first century, people's understanding of metal corrosion transitioned from an empirical stage to a systematic subject research stage. The research on environmental corrosion of modern materials has a history of nearly a hundred years. Taking atmospheric corrosion as an example, the accumulation of metal corrosion data in natural outdoor environments began in 1906. The American Society for Testing and Materials (ASTM) established an atmospheric corrosion test website, and Corrosion tests of a variety of materials have been carried out in an atmospheric environment. In the 1920s, the British Vernon cleaned the surface of the metal sample and exposed it to the outdoor natural environment to measure the corrosion rate and calibrate the main corrosion products. Vernon's experimental research methods have been used until now, but the observation and characterization instruments have been substantially improved. Because of Vernon's experimental research, the subject of corrosion has been transferred from the so-called "art" field to the scientific field. Based on a large amount of natural environmental corrosion data, the corrosion mechanism of metals in the atmosphere has been studied in depth.

Countries all over the world attach great importance to the research on the environmental adaptability of steel and its products in the production, transportation and service process, and actively carry out the accumulation of corrosion data and experimental research of materials in typical natural environments, and grasp the corrosion of various materials in the natural environment Laws, this is of great significance for controlling environmental corrosion of materials and reducing economic losses. The research on the natural environmental adaptability of steel materials is very complicated, and there are many influencing factors, and it is difficult to simulate in the laboratory. It is necessary to pass field test and observation at the field test site to obtain the actual environmental adaptability data. The construction and data accumulation of the material natural environment test station network has a history of hundreds of years. As the natural environmental conditions of various countries are different, there are also great differences.

my country has a vast territory and complex natural environment. The north and south are distributed in 7 climatic zones. As a result, 7 typical atmospheric environments (rural, urban, industrial, ocean, plateau, desert, tropical rain forest) and five major water systems (Yellow River, Yangtze River, Pearl River) are formed. , Songhua River and Huai River), 4 sea areas (Bohai Sea, Yellow Sea, East China Sea and South China Sea) and more than 40 soil types.

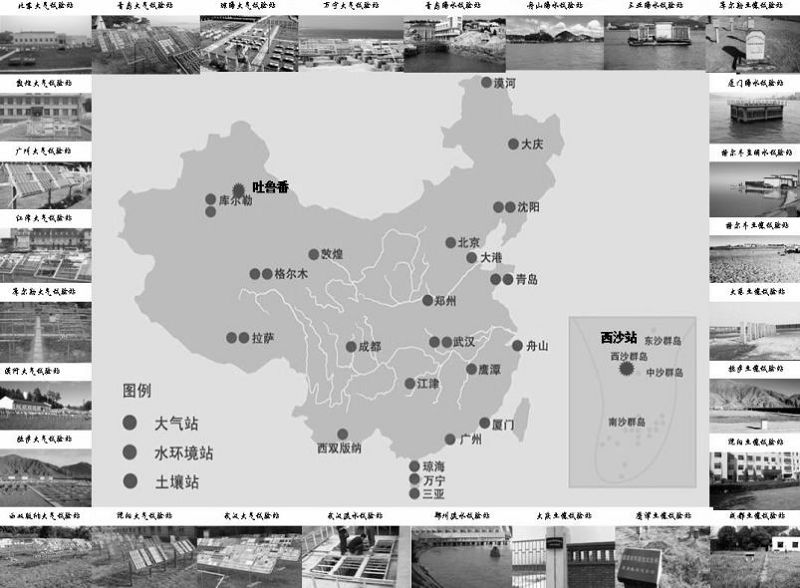

The corrosion rate of materials in different environments can vary several times or even dozens of times, and it is impossible to simply substitute data from developed countries. Only through long-term data accumulation and experimental research can we master the corrosion data and laws of materials under the natural environmental conditions of our country. my country’s natural environmental corrosion test began in the 1950s. After decades of construction and development, according to the basic conditions of my country’s material environmental corrosion stations, a national field station plan was established with the Ministry of Science and Technology to coordinate cross-industry, cross-departmental and cross-regional More than ten units have coordinated to build a national material environmental corrosion platform composed of 31 field test stations and 1 center, as shown in Figure 1. The platform includes 16 atmospheric corrosion, 8 soil corrosion and 7 water corrosion test stations, starting from Korla in the west, Zhoushan Island in the east, Mohe in the north, and Xisha in the south, covering all typical natural environmental zones in my country. A field environmental corrosion test site has been built, and a complete set of environmental corrosion test procedures and technologies have been formulated. These environmental corrosion test procedures have been formed into 28 corrosion industry standards; a material environmental corrosion information resource sharing service platform-China Corrosion and Protection Network (www .ecorr.org), facing all sectors of society, providing material corrosion (aging) material resources and information resources services.

Figure 1 Distribution of test stations of the National Material Environmental Corrosion Platform System

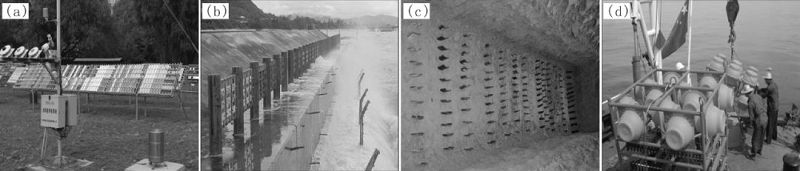

Outdoor environmental exposure test is the most commonly used test method in natural environment test. According to the exposure mode, it can be divided into three types: direct exposure, semi-enclosed exposure and fully enclosed exposure. The selection of the exposure site should mainly consider the effects and effects of various environmental factors on steel products, the representativeness and accuracy of test results, performance changes and speed, etc. The existing domestic natural environmental corrosion test stations have been able to represent the types of typical natural environmental areas in my country. Through studying the influence of environmental factors on the corrosion of steel materials and continuous data accumulation, the corrosion laws of steel materials in typical domestic environments are obtained. In the corrosion-resistant steel research and development and equipment environmental adaptability assessment, my country has established a complete set of field test technologies that meet international standards and have been widely used. The National Material Environmental Corrosion Platform has completed the largest environmental corrosion test of materials in my country, including more than 100 materials such as carbon steel, weathering steel, stainless steel, and coatings. It has been carried out for 16 years in response to the characteristics of my country's vast territory and complex natural environment. The systematic exposure test of the atmosphere, soil and seawater corrosion classification model research, see Figure 2.

(A) Atmospheric environment (b) Water environment (c) Soil environment (d) Deep sea environment

Figure 2 Natural corrosion test of steel in the atmosphere, water, soil and deep sea environment

With the implementation of the national "One Road, One Belt" strategy, the National Material Environmental Corrosion Platform has carried out environmental corrosion tests and data accumulation of steel materials in Southeast Asia since 2015, and carried out natural environmental corrosion in Thailand, Indonesia, Singapore, Malaysia and other places. Tests, these tasks will guide port material selection, ocean engineering and high-speed railway construction and application demonstrations.

Under the trend of globalization of material environmental corrosion observation test research, in order to improve the adaptability of materials to the environment and the comparability of environmental corrosion, the main purpose of observation test research work is to accumulate material corrosion data, from exposure methods to detection methods All adopt unified norms and standards. In developed countries, the development of standardization of material environmental corrosion observation and testing has received extensive attention. In recent years, the United States, Japan, Germany, and other NATO countries have invested a lot of manpower and material resources in the environmental corrosion of materials, conducted a large amount of experimental research and data accumulation, and actively promoted the standardization process of material environmental corrosion observation and testing. The international standardization organization represented by ISO has also established a relatively mature and complete material corrosion observation and test standardization system. At present, there are more than 60 published standards. The United States and other developed countries have established a detailed material environmental corrosion test standardization system suitable for their national conditions. Taking the United States as an example, organizations such as the National Bureau of Standards, Society for Testing and Materials (ASTM), Society of Corrosion Engineers (NACE), Society of Metals (ASM) and American Petroleum Institute (SPI) have researched and formulated thousands of materials corrosion and protection standards. A very specific and complete standard system has been formed. There are more than 800 standards for atmospheric corrosion observation and testing of materials being implemented. The environmental corrosion tests of materials of the Atlas Climate Services Group of the United States are conducted in accordance with ASTM, SAE, MIL, DIN, JIS, Nissan and other standards. Therefore, in the natural environment exposure test research, through scientific and systematic management and the establishment and operation of various standard systems, the authority and scientificity of the environmental corrosion data of steel materials and their products will be further improved. 2 Indoor environment accelerated corrosion test technology

In the natural environment, due to the long failure evaluation cycle of steel materials and the complex and changeable factors of field test, the complete use of field test methods cannot meet the needs of new product development of steel materials and material corrosion life evaluation and prediction. Therefore, it is necessary to establish accelerated corrosion test technology for steel materials to predict the long-term service behavior and service life of steel and its components in actual environments.

At home and abroad, it is generally believed that the indoor environment accelerated corrosion test cannot simply replace the natural environment corrosion exposure test. The evaluation standard of the laboratory accelerated corrosion test depends on the correlation between indoor and outdoor corrosion tests.

Due to strong theory, diverse environments, many influencing factors, insufficient data and case accumulation, the accelerated corrosion test technology with good indoor and outdoor correlation has been delayed for a long time. Therefore, the development of new theories and new technologies for environmental accelerated corrosion evaluation of serialized materials has great practical value and scientific significance, and is also one of the key points in the research of environmental test technology for steel materials. The following is an introduction from the development of indoor simulation accelerated test technology for atmospheric, seawater and soil environmental corrosion.

Early atmospheric corrosion indoor simulation accelerated methods mainly used damp heat test methods, including accelerated corrosion tests that simulate corrosive gases by introducing SO2, H2S, CO2, etc. ASTM formulated three salt spray test standards in 1962, namely, neutral salt spray test, acetic acid salt spray test and acetic acid copper chloride salt spray test. At present, salt spray test is still the most commonly used method for accelerated simulation test of marine atmospheric corrosion. However, a large number of experiments have proved that the salt spray test method can only be used as an artificial accelerated corrosion test method, and cannot simulate the environment containing chloride ions such as the ocean. Various single salt spray tests are not good for the simulation of atmospheric exposure. The main reason is that the salt spray test does not have a "wet-dry" cycle. Under natural atmospheric conditions, the sample is formed by rain, fog, etc. The liquid film has a cyclical process from thick to thin, and from wet to dry. Therefore, some scholars have proposed a salt spray compound test method with periodic salt spray during the drying process. In 1980, Japanese scholars proposed a method of periodic infiltration compound cycle test. This accelerated simulation method has good reproducibility. Pourbaix uses this method to study atmospheric corrosion. By periodically immersing in distilled water, NaHSO3 or NaCl solutions, it simulates accelerated atmospheric corrosion in rural, industrial, and marine atmospheres, respectively. Research has shown that several weeks of experiments can be compared to one year or one year. Matches with longer natural exposu In recent years, foreign scholars have combined periodic spraying and periodic infiltration tests, and a variety of environmental factor cyclic compound corrosion tests have appeared. It not only realizes the control of environmental factors such as temperature, relative humidity, dry and wet frequency, dry/wet alternation, pollutant SO2, CO2 content, and wind speed, but also simulates atmospheric corrosion under various meteorological conditions and obtains and real atmospheric exposure tests Similar data. At present, the international research on simulated atmospheric corrosion accelerated test has developed from single or several environmental factors to multi-factor compound accelerated corrosion. When conducting accelerated test research, it is not a simulation of atmospheric corrosion phenomena, but a simulation of the essential laws of atmospheric corrosion. Over the years, the research on the environmental spectrum of the material atmospheric environment equivalent accelerated test has been highly valued by the academic and engineering communities at home and abroad, especially in developed countries regarding the law of the influence of the corrosive environment on the life of aircraft structures and other equipment, the method of life prediction in the corrosive environment, and the structure Many fruitful researches have been carried out on corrosion control, accelerated corrosion test technology and environmental spectrum of structural simulation parts laboratory.

Using indoor simulation accelerated experiment methods, based on the accumulation of a large amount of corrosion data, the National Material Environmental Corrosion Platform Comprehensive Research Center determined the simulation that meets the characteristics of the Xisha atmosphere according to the field conditions, especially the high temperature, high humidity, and high salt fog ocean atmosphere of Xisha Solution, designed periodic infiltration + salt spray corrosion environmental spectrum indoor accelerated test method, designed a series of atmospheric corrosion accelerated test equipment such as periodic infiltration corrosion test box, trace corrosive gas environment test box, simple and fast electrochemical test device and automatic The electrolytic cell device that controls the thickness of the thin liquid has developed a reference electrode suitable for electrochemical testing of thin liquids and other atmospheric corrosion mechanism research and test technologies. On the basis of the serialized technology of accelerated corrosion test of atmospheric corrosion, the actual situation, influencing factors, gray correlation analysis, environmental spectrum compilation and indoor accelerated test of atmospheric outdoor exposure materials were systematically studied, and a more systematic and reliable environment was established. Spectral accelerated test methods and life evaluation theoretical systems have been widely used in aviation, aerospace, electronics, and automotive industries.

The marine environment is one of the harshest natural environments for material corrosion. The real sea corrosion coupon test is a reliable corrosion test method in the marine environment, but this test cycle is long and expensive. In order to obtain a large amount of test data in a short time, the marine corrosion indoor simulation accelerated test method and evaluation technology have been developed. The author team A series of new marine corrosion indoor simulation accelerated test devices and deep-sea environment corrosion performance simulation accelerated test devices have been developed, as shown in Fig. 3, and the accelerated corrosion test of materials in shallow and deep sea environments has been studied.

Figure 3 Marine corrosion simulation accelerated test technology and series of devices

The marine corrosion indoor simulation accelerated test device realizes the function of alternating dry and wet, different corrosive gas environment control and simulation of different marine corrosion zones (ocean atmosphere, splash zone, tidal range, and full immersion zone), and can be used simultaneously The indoor simulation/accelerated corrosion test and electrochemical test under complex marine environmental conditions are suitable for the accelerated test of corrosion simulation of various metal materials in the marine environment in the laboratory.

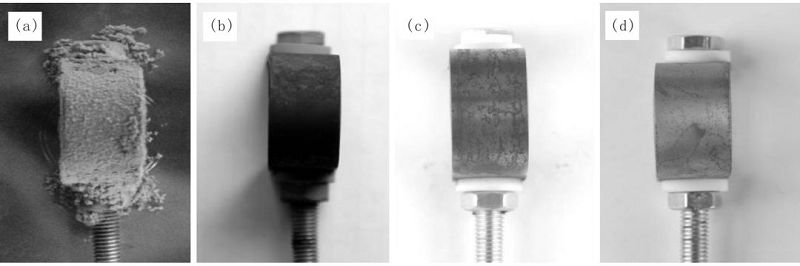

It has been verified that the simulated accelerated test device can simulate ocean multi-zone corrosion and ocean erosion corrosion behavior. The material deep-sea environmental corrosion performance test device in Figure 3 uses a flow circulation system to control the physical and chemical parameters of seawater (such as dissolved oxygen, temperature, pressure) And salinity, etc.), the pressure can be increased to more than 50 MPa (only converted to pressure, equivalent to 5 000 m deep sea). The device truly simulates the low-temperature and high-pressure working conditions of steel materials in the actual deep-sea environment, and solves the problems that the existing deep-sea experiments take long time to obtain experimental data, the data type is single, and the static autoclave cannot truly simulate the actual deep-sea environment. Using this device, we can understand the corrosion behavior of typical metal materials under different pressures, media and other characteristics in the simulated deep sea environment. Figure 4 shows the surface corrosion behavior of X70 pipeline steel in simulated seawater environments at different depths.

(A) 0 m surface (b) 0 m inner layer rust (c) 860 m (d) 1 200 m

Fig. 4 Macro morphology photos of X70 steel U-bend specimens after immersion under different simulated depth conditions

The environmental factors affecting soil corrosion of steel materials are complex. Using the results of short-term accelerated corrosion tests to predict the long-term corrosion behavior and service life of steel materials has always been one of the difficulties in environmental corrosion test and evaluation technology. At present, my country has developed a series of steel soil corrosion test equipment and evaluation methods, and developed a soil corrosion simulation accelerated test box, as well as technology for grooving corrosion sensitivity testing and evaluation. These methods and related standards have been promoted in the industry Application has promoted the evaluation and development of new corrosion-resistant high-strength pipeline steel.

The National Material Environmental Corrosion Platform selects representative soils in Yingtan and Korla area as the main research objects, and selects soils from six other typical regions in China as a comparison to analyze the corrosion types of steel pipelines in typical soil environments. Through the analysis of the corrosion data of Q235 steel, X70 steel to X120 steel and other materials, the evaluation indexes of soil corrosion were established and screened from the three perspectives of uniform corrosion, pitting corrosion and stress corrosion, and the gray correlation model was applied, combined with genetic algorithm and other data. Correlation analysis methods selected soil resistivity, water content, soil pH value, soil texture, redox potential, pipe-to-ground potential, salinity and Cl- content as key soil corrosive environmental parameters, and then established a foundation based on this "Comprehensive Evaluation Method for Soil Corrosion of Buried Steel Pipelines" with 8 soil property indicators. After verification of the existing data of 8 national soil stations, the above method is highly consistent with the actual data. Compared with foreign methods (DIN-50929 and ANSI A21.5), this method not only adopts the internationally universal multi-index soil corrosion evaluation method, but also makes up for the lack of practicality of the soil corrosion evaluation method in the international mainstream standards, and improves The practicability and accuracy of the comprehensive evaluation method of multi-index soil corrosion are discussed.

3 Online corrosion monitoring and big data evaluation technology

With the development of information technology, the United States proposed the "Material Genome Project" in 2011. The concept of data sharing and computing tool development is in line with the material corrosion platform's insistence on data sharing and continuous development of simulation computing research. The "Material Corrosion Informatics" published in 2014 and related work pointed out that the goal of the Material Genome Project is to shorten the existing material research and development cycle from 20 to 30 years to 2 to 3 years, which requires innovation in material corrosion research. Make breakthroughs by using simulation calculations and data cross-sharing to develop new efficient and reliable corrosion test methods, new environmental severity classification standards, new multi-scale corrosion behavior new theories and new life prediction models. Taking the monitoring and evaluation of atmospheric corrosion of steel as an example, the research progress and application of corrosion test and big data evaluation technology are briefly explained.

The corrosive damage of metal materials in the atmosphere is mainly caused by alternating humid and dry climates. The corrosion process is due to the electrochemical corrosion of metal under the thin liquid film. Therefore, the atmospheric corrosion process not only meets the general laws of electrochemical corrosion, but also has its own characteristics. At present, the atmospheric corrosion monitoring (ACM) instrument is still an important tool for studying atmospheric corrosion. The ACM instrument reflects the corrosiveness of the atmospheric environment according to the current signal of the thin film electrochemical cell. Among them, the ACM battery, as an important part of the monitor, is designed based on the principle of galvanic corrosion in the principle of corrosion electrochemistry.

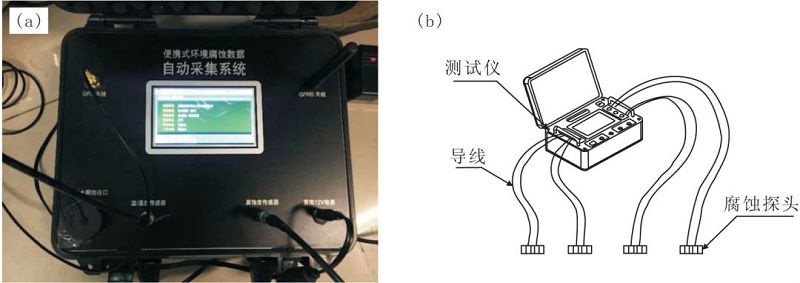

The author has developed a multi-channel atmospheric environment corrosion monitoring device suitable for high-throughput data collection, as shown in Figure 5. This monitor can select multiple typical atmospheric environments to monitor the corrosion degree of steel materials in different spaces and times on-line. The atmospheric corrosion monitoring probe reflects the corrosiveness of the atmospheric environment by measuring the current signal of the electrochemical cell under the thin liquid film, and preliminarily analyzes the main environmental factors of atmospheric corrosion in different areas and the characteristics of the corrosion environment based on the data provided. The atmospheric corrosion monitoring probe can be customized according to the monitored space and working conditions, and is especially suitable for monitoring the trend of environmental corrosion.

Figure 5 ACM testing equipment

The ACM equipment application system adopts B/S architecture and Java language, supports cross-platform operation, supports GIS map display, and can display and store the environment climate in real time. The interface dynamic instrument graphically can display microclimate monitoring point data. The equipment also has Monitoring point historical data query and graphical output and analysis functions. The ACM monitoring technology based on Internet big data realizes the intelligent monitoring of corrosion big data, and makes up for the instability and data monitoring of the coupling of multiple environmental factors in the process of traditional coupon experiment design, fragmentation, and data accumulation. Hysteresis and other shortcomings have realized the real-time intelligent automatic collection of big data (temperature, humidity, chloride ion concentration, SO2 concentration, particulate matter content, etc.) of the corrosion environment, high-throughput calculation and analysis of material informatics, and real-time intelligence of the corrosion process The functions of chemical monitoring and other functions will eventually form a steel material service data sharing platform with the characteristics of "corrosion big data". Through this platform, online collection, data analysis, processing and mining and information management of corrosion data during the service of steel materials are realized, providing new methods for realizing the safety and health diagnosis of steel materials and their components, and further developing the corrosion of steel used in islands and reefs. Protection technology. 4 Conclusion Focusing on the urgent needs of national economic construction and strategic layout, we will continue to improve the environmental corrosion test methods of steel materials in natural environments, and continue to carry out steel materials and products in typical natural environments at home and abroad and harsh and extreme environments (deep / open sea, west / Nansha , South/Arctic, etc.), to enrich and improve the environmental corrosion database of steel products; on the basis of multi-period and long-sequence data, to further develop the comprehensive application and practice of information technology such as modeling, simulation and knowledge mining, fully understand and Reveal the scientific laws and mechanisms of environmental corrosion of steel materials; improve the environmental corrosion evaluation standard system of steel materials, so that the natural environmental corrosion test research work of domestic materials is in line with international standards, and contributes to improving the quality of steel products and strengthening the international competitiveness of China's steel.

|

Scan the QR code to read on your phone

- CONSULT

- TEL 86-23-67787593

- BACK

Service hotline:

Fax:023-67787596

Web:www.cqdayou.com

E_mail:cqdayou@cqdayou.com

Add:66 Sendi Avenue, Xipeng Town, Jiulongpo District, Chongqing

Copyright © 2020 Chongqing Dayou Surface Technology Co., Ltd. All Right Reserved 渝ICP备16005686号

Copyright © 2020 Chongqing Dayou Surface Technology Co., Ltd.

渝ICP备16005686号