TECHNICAL INTRODUCTION

Contrast

- Categories:TECHNICAL

- Time of issue:2018-11-14 00:00:00

- Views:0

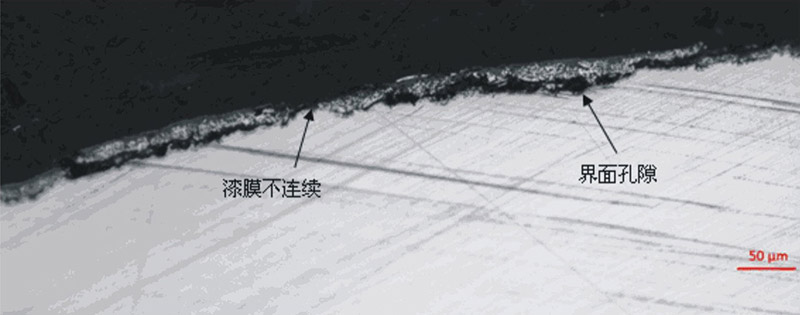

Dacromet metallographic figure

Dacromet metallographic figure

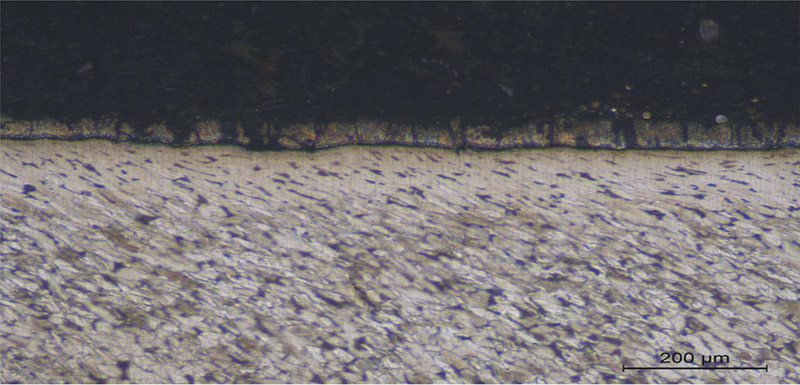

Electrostatic spraying metallographic figure

Electrostatic spraying metallographic figure

Zinc impregnation metallographic figure

Zinc impregnation metallographic figure

Zinc-nickel infiltration layer metallographic figure

Zinc-nickel infiltration layer metallographic figure

Comprehensive Comparison of Various Surface Treatment Technologies

|

Comparative Item |

Cold Galvanizing |

Hot-Dip Galvanizing |

Dacromet |

Powder Zinc Impregnation |

Zinc-aluminum Multi-Component Thermochemical Treatment |

Zinc-nickel Infiltration Layer |

|

Acid Pickling |

Yes |

Yes |

No |

Yes |

No |

No |

|

Hydrogen Embrittlement |

Yes |

Yes |

No |

No |

No |

No |

|

Neutral Salt Spray Test(h) |

≤100 |

≤480 |

≥1000 |

≥240 |

≥500 |

Maximum6000 |

|

Sulfur Dioxide Resistance |

difference |

difference |

difference |

difference |

difference |

Good |

|

Adhesive Force |

Better |

Better |

Difference |

Better |

Better |

Good |

|

Hardness(HV) |

180-200 |

70-80 |

2H |

>250 |

>250 |

200-500 |

|

Wear Resistance |

Poorer |

Better |

Difference |

Better |

Good |

Good |

|

Appearance Homogeneity |

Good |

Difference |

Good |

Better |

Good |

Good |

|

Cooperation Influence |

Less |

Gig |

Less |

Less |

Less |

Less |

NOTE: Vary depending on the material and heat treatment process.

Elastic strip surface residual stress

|

|

0 ° direction residual stress(MPa) |

90°direction residual stress(MPa) |

|

Before zinc-nickel infiltration layer |

-49.5±4.6 |

-69.0±4.3 |

|

-114.5±30.9 |

-81.1±27.4 |

|

|

-70.0±23.0 |

-63.0±18.0 |

|

|

After zinc-nickel infiltration layer |

-282.6±4.6 |

-329.8±8.5 |

|

-195.8±7.4 |

-299.8±6.4 |

|

|

-340.0±15.5 |

-294.3±19.8 |

Comparison of zinc-nickel infiltration layer and Dacromet fatigue life (wind power bolt)

Hardness after zinc-nickel infiltration layer of different materials and heat treatment states

|

Hot-rolled low carbon steel (Q235) – diffusion layer hardness is slightly higher than substrate hardness |

|

Product |

Sample No. |

Diffusion Layer |

Average |

Matrix |

Average |

|

HV0.025 |

HRB |

||||

|

Gauge Apron |

1 |

200 208 189 |

199 |

65.5 65.0 66.0 |

66.0(130HV) |

|

2 |

198 232 215 |

215 |

67.0 65.5 65.0 |

66.0(130HV) |

|

|

3 |

232 203 232 |

222 |

70.5 69.5 66.5 |

69.0(135HV) |

|

|

4 |

196 189 173 |

186 |

67.0 67.5 70.0 |

68.0(135HV) |

|

|

Screw Spike |

1-1 |

271 283 247 |

267 |

82.0 81.5 82.0 |

82.0(170HV) |

|

1-2 |

251 232 241 |

241 |

80.0 80.0 79.0 |

79.5(165HV) |

|

|

2-1 |

226 215 221 |

221 |

82.5 81.5 82.0 |

82.0(170HV) |

|

|

2-2 |

208 215 205 |

209 |

80.0 81.0 79.0 |

80.0(165HV) |

|

Hot-rolled Mmedium carbon steel (45 steel) and non-quenched and tempered cast iron – diffusion layer hardness is slightly higher than the substrate hardness

|

Product |

Diffusion Layer |

Average |

Matrix |

Average |

|

HV0.1 |

||||

|

45 Steel |

351 374 353 351 356 |

357 |

276 274 271 270 276 |

273 |

|

QT400-15 |

325 325 321 320 327 |

324 |

232 238 230 235 238 |

235 |

Quenching - carbon alloy steel in tempering - diffusion layer hardness is slightly lower than substrate hardness

|

Product |

Diffusion Layer |

Average |

Matrix |

Average |

|

HV0.1 |

||||

|

Ⅱ-type elastic strip(60Si2CrA) |

433 429 436 414 429 |

428(44.0HRC) |

468 460 468 464 456 |

463(46.5HRC) |

|

Wind power bolt(42CrMoA) |

338 328 331 346 344 |

337(36.5HRC) |

375 352 378 346 357 |

362(39.0HRC) |

|

321 311 326 326 314 |

320(35.0HRC) |

358 354 344 346 354 |

351(38.0HRC) |

|

|

366 346 352 375 362 |

360(39.0HRC) |

358 357 360 366 378 |

364(39.5HRC) |

|

Scan the QR code to read on your phone

- CONSULT

- TEL 86-23-67787593

- BACK

Service hotline:

Fax:023-67787596

Web:www.cqdayou.com

E_mail:cqdayou@cqdayou.com

Add:66 Sendi Avenue, Xipeng Town, Jiulongpo District, Chongqing

Copyright © 2020 Chongqing Dayou Surface Technology Co., Ltd. All Right Reserved 渝ICP备16005686号

Copyright © 2020 Chongqing Dayou Surface Technology Co., Ltd.

渝ICP备16005686号